R&D

- R&D

- Production Line

Production Line

Production Line

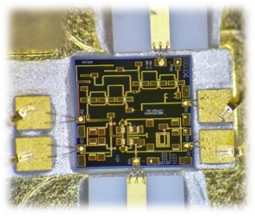

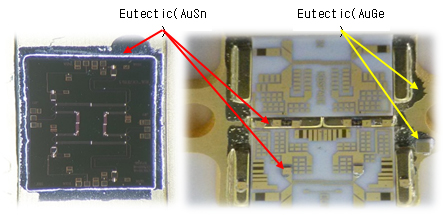

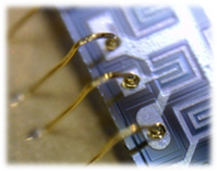

WISTEK's production team's mission is largely divided into two categories : the Hybrid (Chip&Wire) Process and the Assembly/Test Process.

Hybrid Process

| Process Type | Process Content | Facilitity |

|---|---|---|

| Plasma and Ultrasonic Cleaning | Cleaning or removing foreign substances attached to parts or equipment |

|

| Die Attach (Epoxy & Eutectic) |

Placement and pasting of elements as specified in the drawing |

|

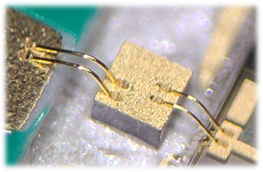

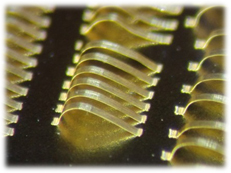

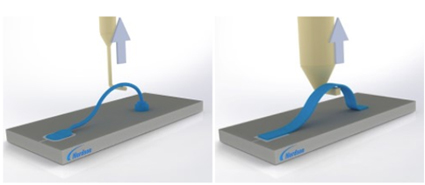

| Wire & Ribbon Bonding |

Connecting the pattern of each device or substrate (PCB) using wire or ribbon so that it can have electrical characteristics in a circuit |

|

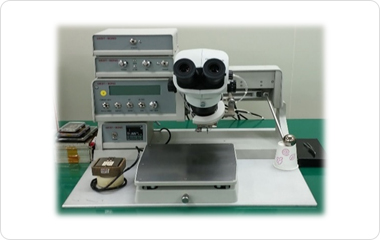

| Wire & Ribbon Pull Test | Destructive and non-destructive testing (tensile force test) to check the connection status of the wire or ribbon connected to the device or substrate (PCB) pattern |

|

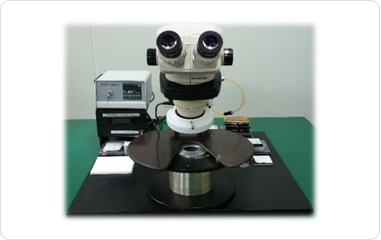

Equipments for Hybrid assembly

Ribbon Bonder

Auto Wire Bonder

Wire Bonder

Wire Pull Test

Eutectic Attach

Oven

Plasma Cleaner

Cryogenic Freezer

Assembling and Testing

| Work Type | Work Content |

|---|---|

| Hand(Iron) Soldering | Attaching and connecting devices on the PCB according to the drawings |

| Module Assembling | Assembling products according to drawings or working procedures |

| RF Test and Tuning | The work of testing and adjusting the characteristics of the assembled product using an RF instrument according to the test procedure |

| Bad Trouble Shooting | When a product is tested or a serious defect or issue occurs in a delivered product, the task of finding and solving the cause |

RF Measurement Facilities for Testing

Noise Figure Analyzer

Power Meter

Signal Source Analyzer

Network Analyzer

SIGNAL GENERATOR

OSCILLOSCOPE

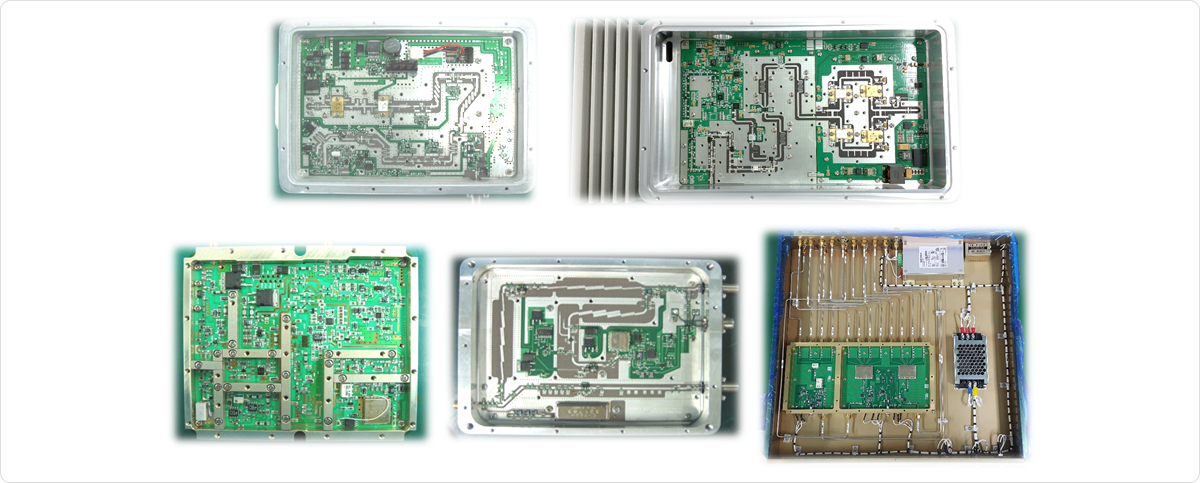

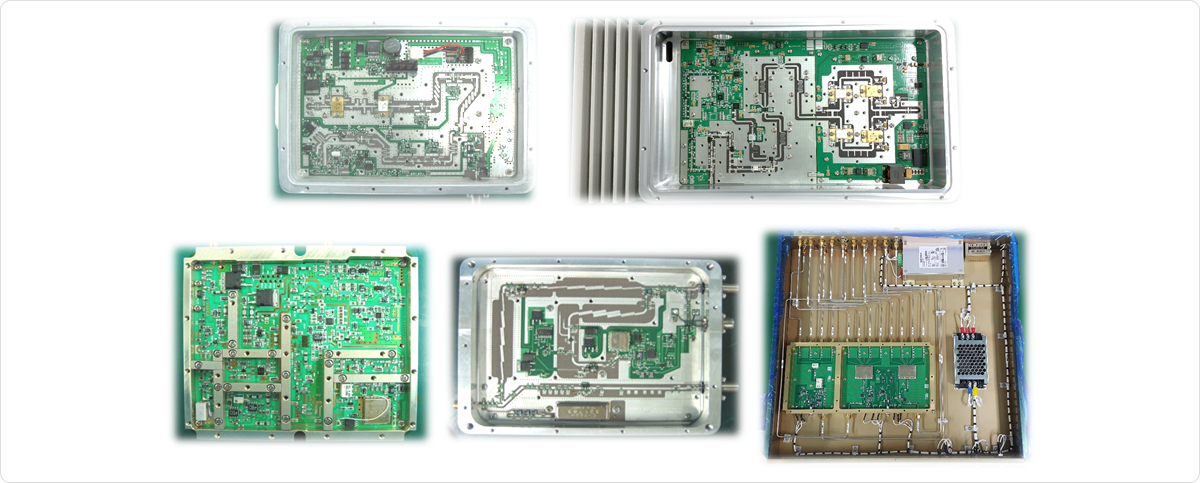

Products

Work Look